Visco Machine

Visco Machine

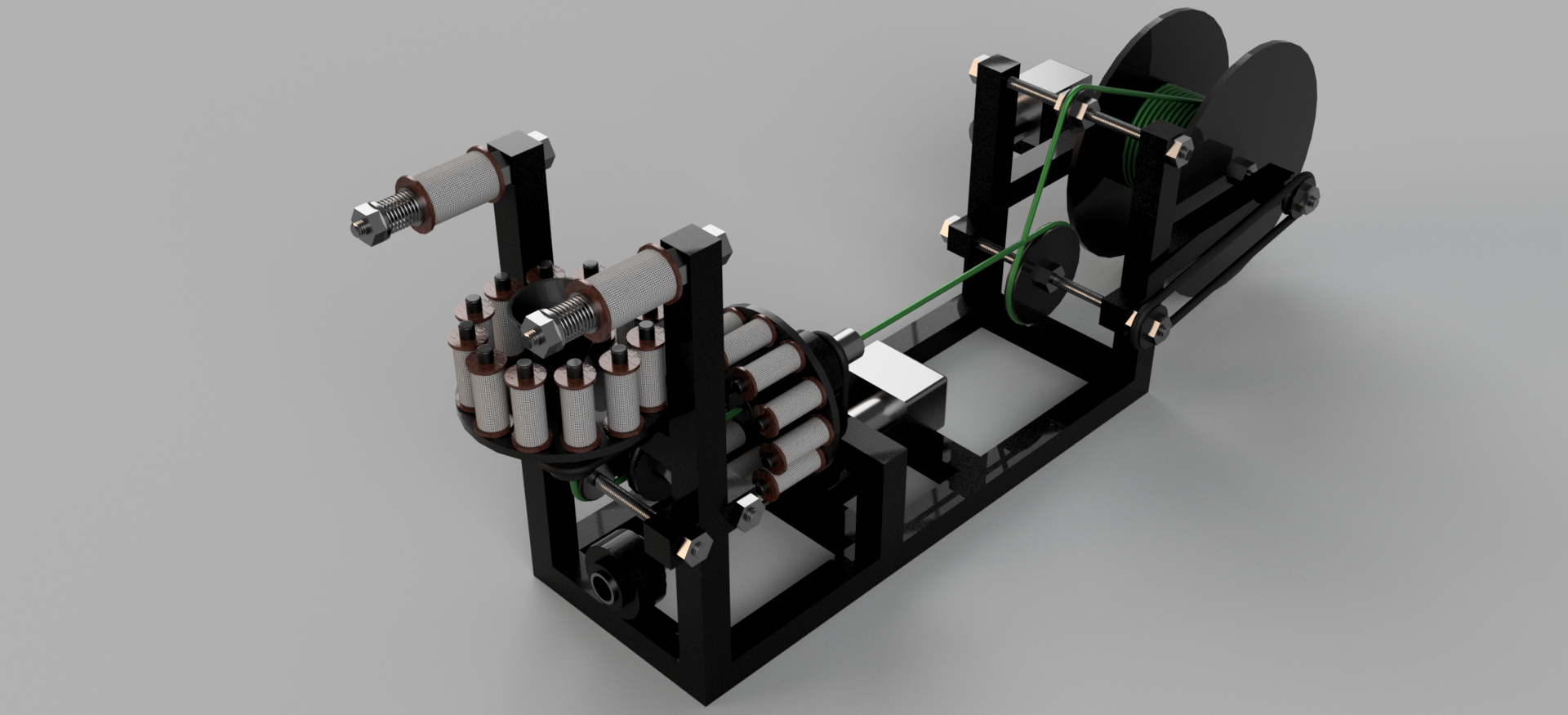

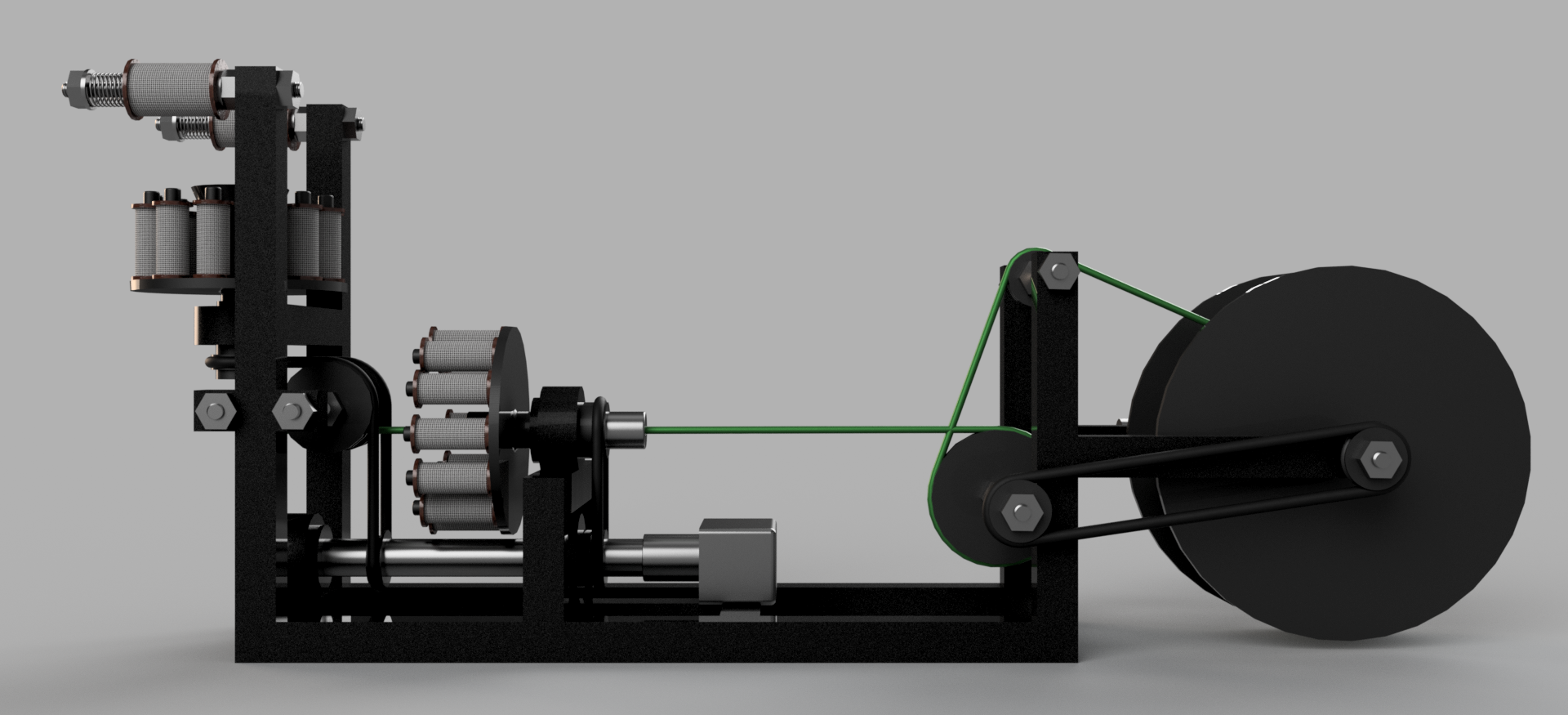

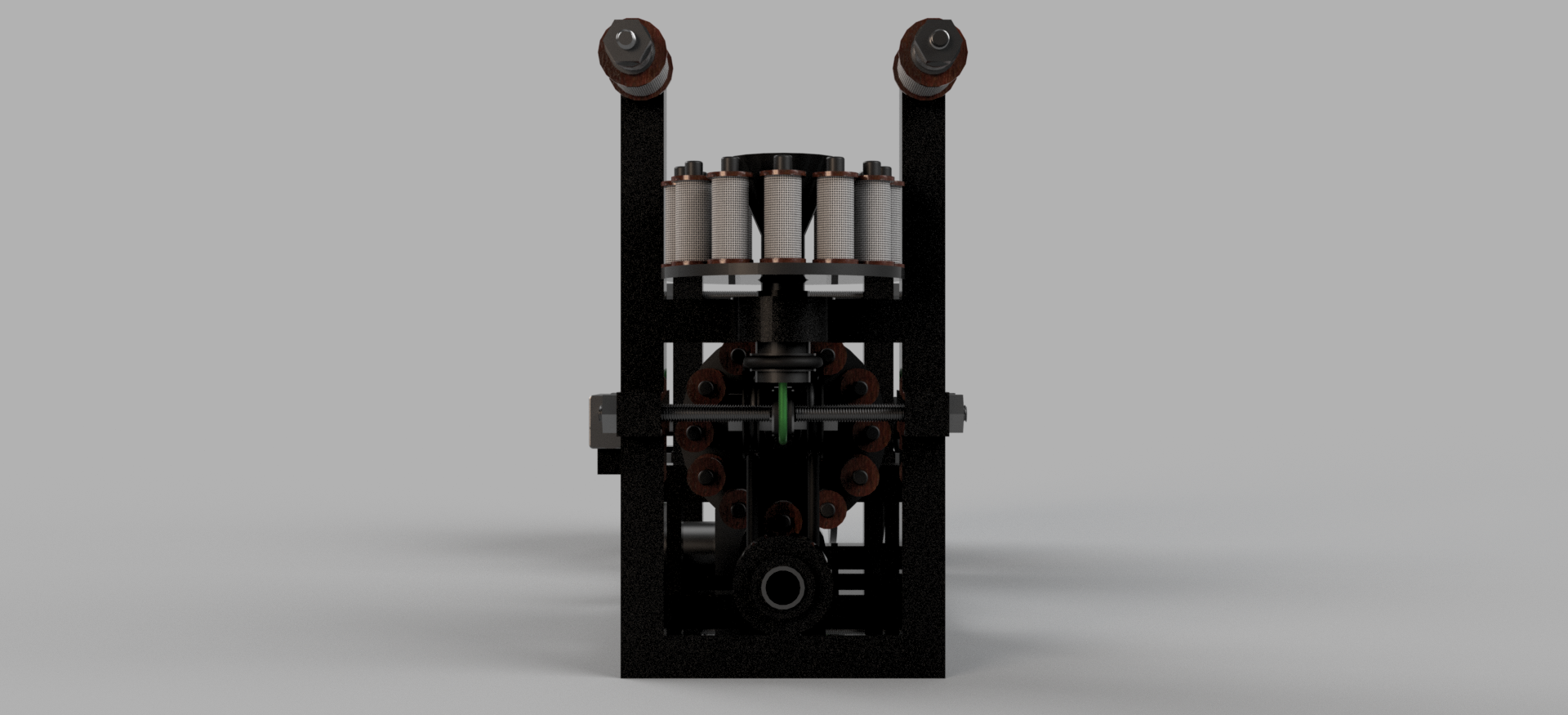

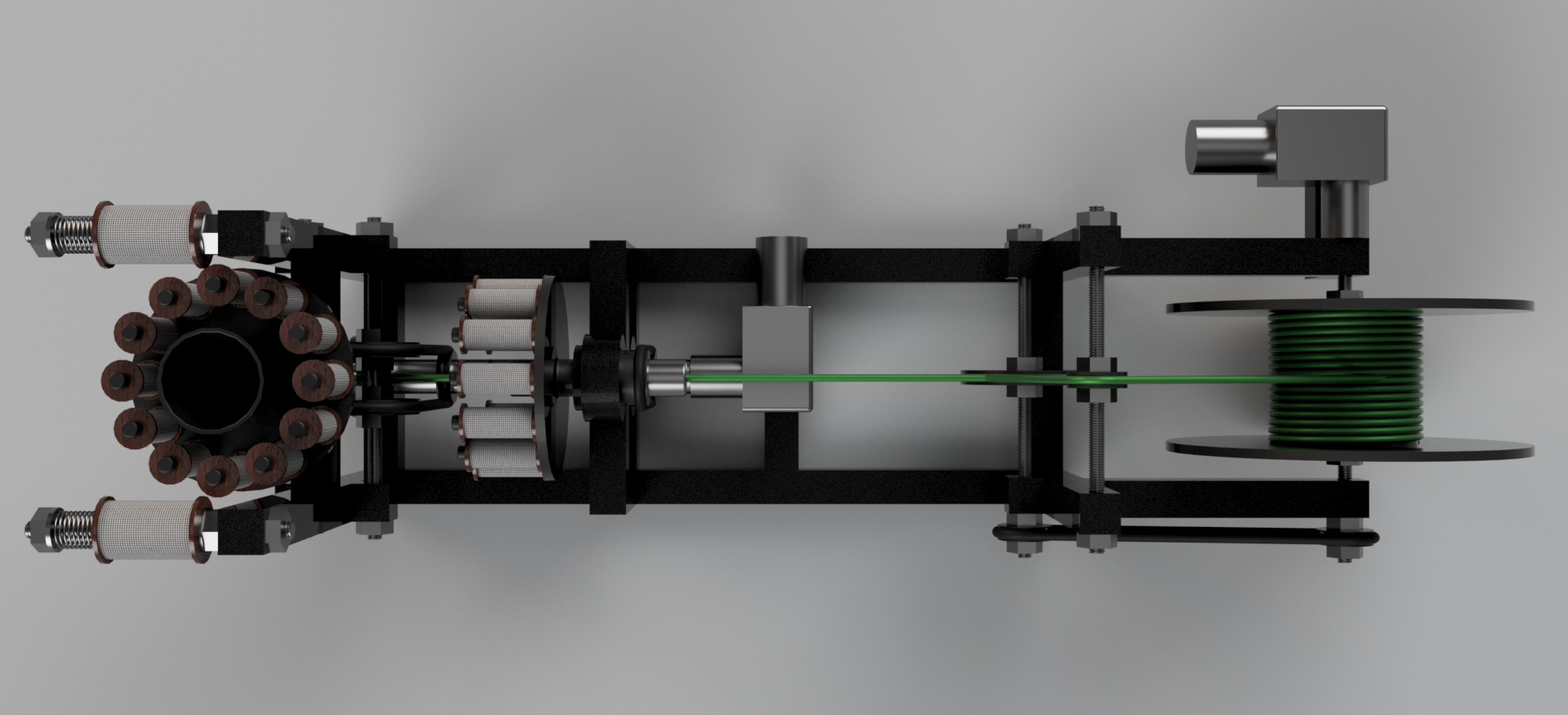

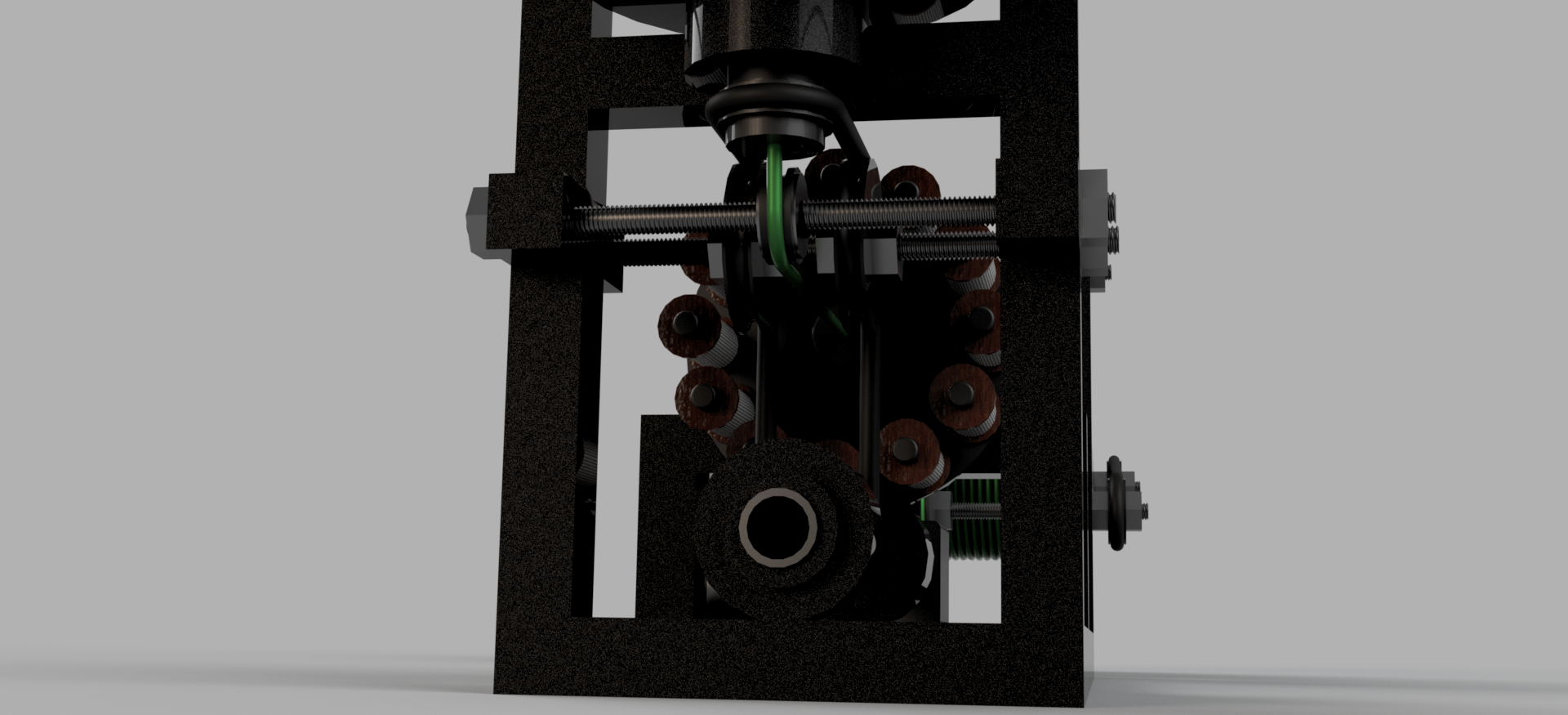

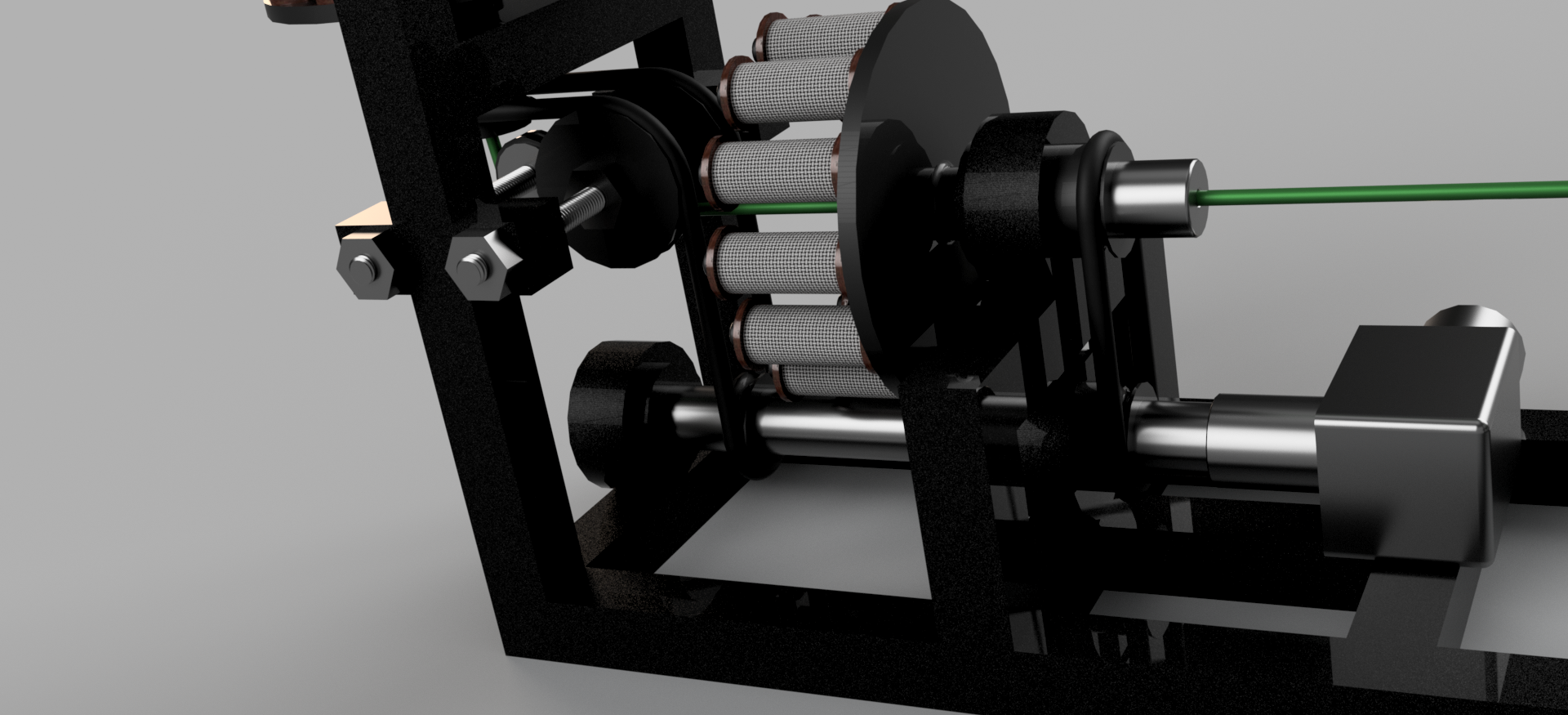

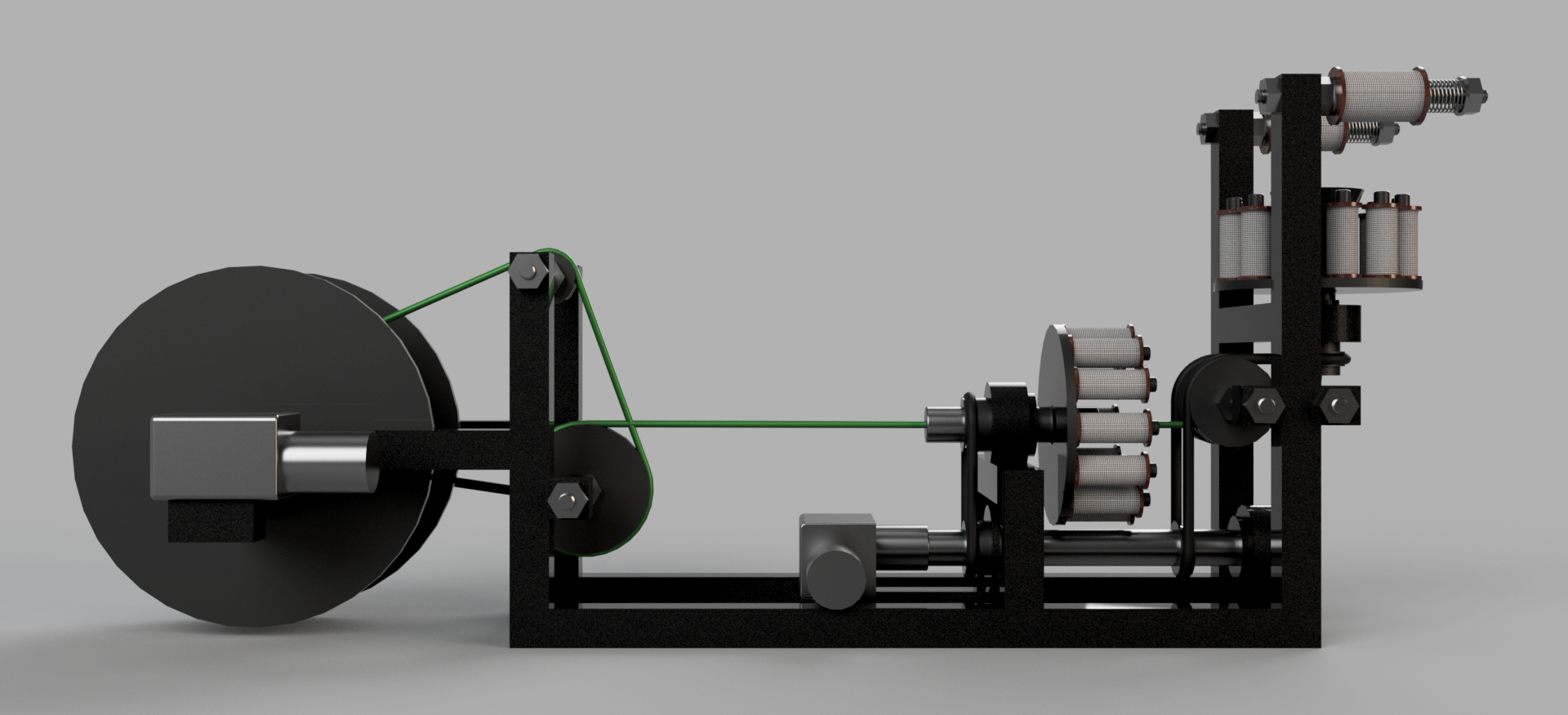

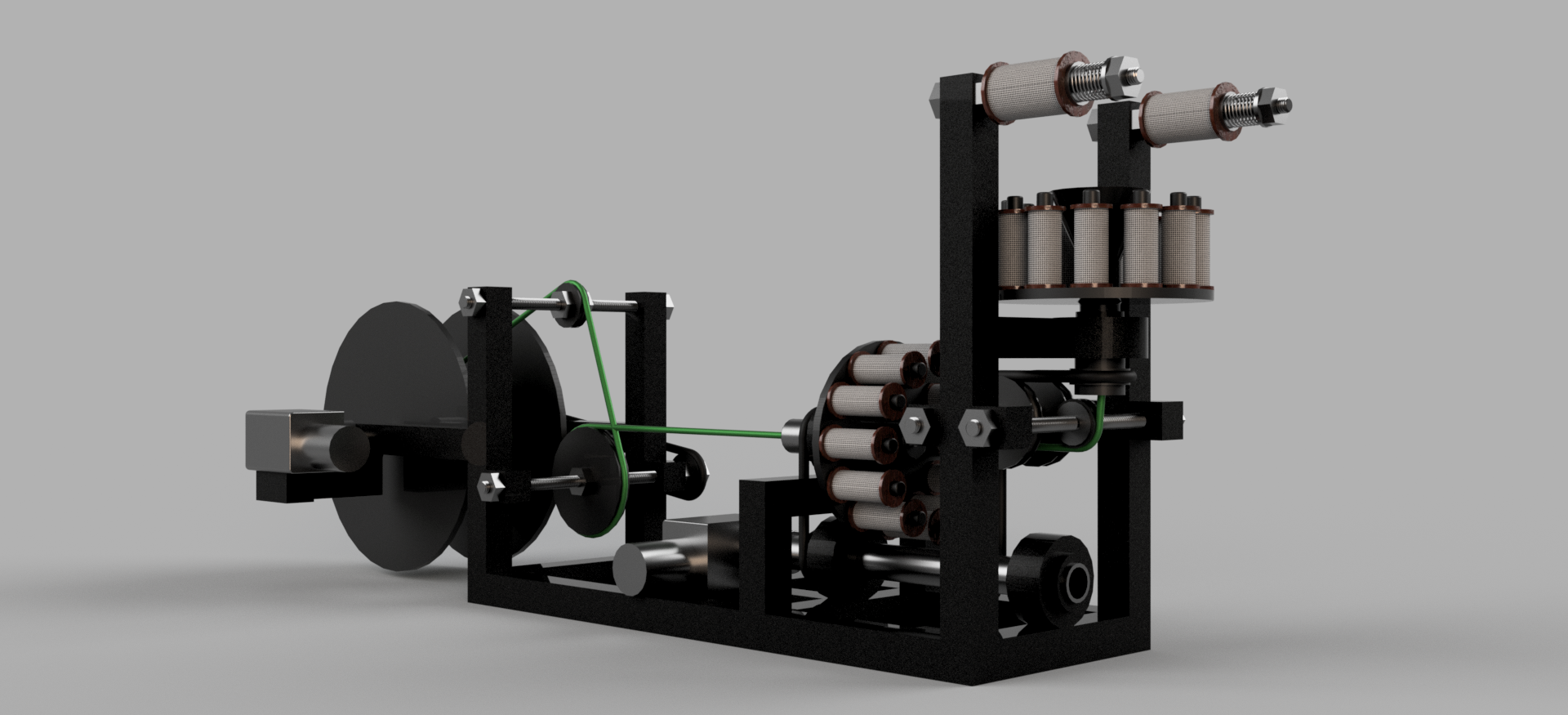

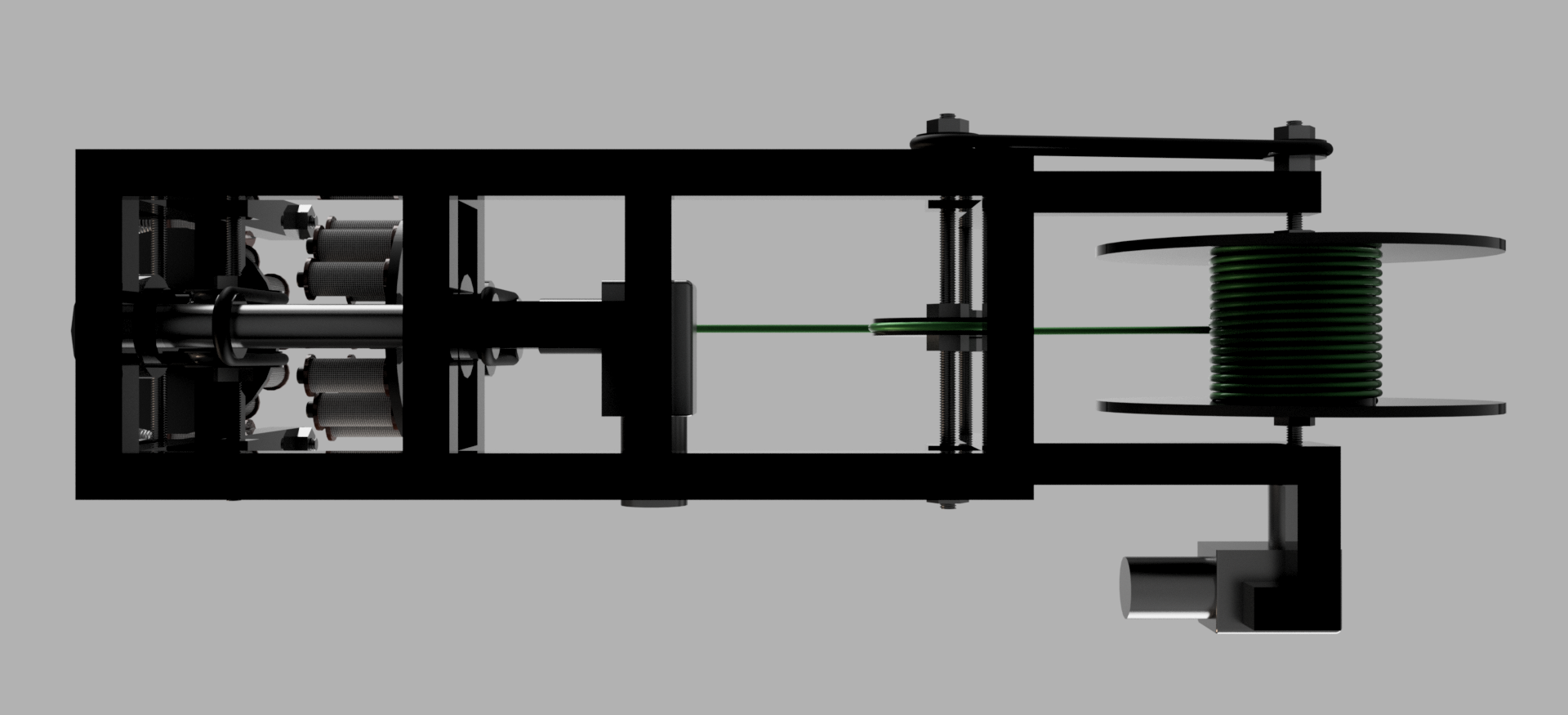

This machine is used to make your own Visco fuse. The frame of the machine is made out of welded steel beams that hold the two electronic motors which control the RPMs of the turning discs loaded with string as well as the speed in which the fuse gets pulled out of the machine. The fuse produced by the machine needs to be coated in nitrocellulose lacquer to burn in a constant and reliable speed.

The space in the back of the machine can be used exactly for that purpose. You can attach a bowl of nitrocellulose lacquer to the frame and let the fuse run trough it. At the end of the process, you will end up with a 3mm thick visco fuse ready to be tested and used. Most of the machine is made out of metal and steel but some parts are 3d printed as well to get better quality of the fuse. The RPMs of the motors can be controlled via two controllers. This impacts how tightly the fuse will be winded and will impact the fuses quality. The turning moment of the motors is transferred on to the other axils by using rubber belts attached to the machines moving parts. Configure your machine down below!

Options

Steel, Aluminium and PLA+

The RPMs of the two motors are controlled via two controllers. This impacts how tight the windings are and therefore the quality of the fuse. The machine is powered via a 12 volts power supply with an European power plug. If that dosn´t fit your needs let us know!

– Nitrocellulose Lacquer Container

The container is placed between the exit of the finished fuse and the spool at the back of the machine. Therefore, the fuse will run through the nitrocellulose lacquer before getting winded on the spool.

-Excluded Spool

You have the option to exclude the spool at the very end on which the Visco gets spooled on and make your own one or use one you have at home.

-Black

-White